Metal fabrication industries face increasing demands for precise and efficient forming operations. Manufacturers struggle with maintaining consistent quality while meeting tight production schedules.

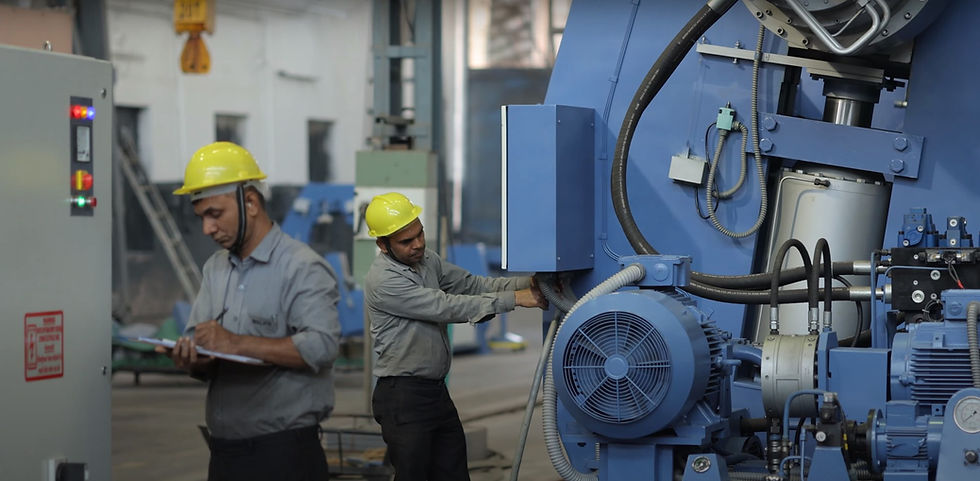

Modern plate bending machine technology addresses these critical challenges in metal fabrication. Understanding these machines helps manufacturers optimize their production processes and outcomes.

Proper machine selection and operation directly impact product quality and profitability. Expert knowledge of bending components ensures optimal performance and reduced operational costs.

This blog explores the essential components of power plate bending operations. Readers will discover key machine elements, their functions, and maintenance requirements. The discussion covers frame structures, rolling systems, control mechanisms, and safety features.

Understanding the Plate Bending Machine

Plate-bending machines have transformed metal fabrication since their introduction in the 1900s.

Modern plate-bending machines combine mechanical force and precision controls to shape metal sheets. Computer numerical control systems have revolutionized the accuracy and repeatability of bending operations.

Key aspects include:

Precise angle control within an accurate degree of tolerance

Reduced manual labor requirements

Integration with automated production lines

The evolution from manual to automated bending has increased manufacturing efficiency and quality. These advancements have made plate-bending machines essential in industries like shipbuilding and construction.

Essential Bending Machine Parts and Functions

Now that we understand what is a rolling machine used for, we can explore its components. Metal fabrication success depends on understanding the machine's core operational elements. Here are the essential components that make plate bending operations possible.

Frame and Support Structure

The frame serves as the foundation for all mechanical operations in plate bending.

A robust structure distributes forces evenly throughout the machine during metal forming processes. The integration of bending machine components relies on the frame's stability and strength. Heavy-duty steel construction prevents distortion when processing thick metal plates under pressure.

The main characteristics of industrial frames include the following:

Wide-ranging load capacity for diverse manufacturing needs

Reinforced welded joints for enhanced structural integrity during continuous operations

Anti-vibration mounts to reduce operational stress and maintain precision

Strategic support points for optimal weight distribution across the frame

Modular construction enables customization for different bending capacities and applications

Industrial-grade steel composition ensures longevity under extreme working conditions

Integrated safety guards and emergency stop mounting points for operator protection

Built-in cable management and control panel locations for efficient workspace organization

The frame incorporates mounting points for hydraulic systems and mechanical drive assemblies. Modern designs feature modular construction to accommodate different bending capacities and configurations.

The support structure includes precision-engineered components to maintain alignment during operation. Industrial-grade materials ensure longevity under continuous heavy-duty bending operations daily.

Safety considerations have shaped frame designs to protect operators during bending processes. The base structure includes leveling mechanisms for precise alignment on workshop floors.

Advanced frame designs incorporate dedicated spaces for control systems and electrical components. Strategic placement of reinforcement points ensures consistent performance under maximum load conditions.

Rolling and Bending Systems

Rolling systems transform flat metal sheets into curved or cylindrical shapes through mechanical force.

The core bending machine components work together to apply controlled pressure during forming. Multiple roller configurations allow for different bending profiles and material thicknesses simultaneously.

Key features of modern rolling systems include:

Hardened steel rollers with surface treatments for extended service life

Hydraulic positioning systems with high accuracy

Digital readouts providing real-time feedback on bending angles and positions

Synchronized motor drives ensure uniform pressure distribution during the operation

Pre-bending capabilities for processing plates without leaving unbent edges

Automated roller adjustment systems for varying material thicknesses

Smart sensors monitor roller alignment and material position throughout the operation

Force-feedback mechanisms preventing material damage during complex bending processes

The bending mechanism incorporates planetary gearboxes for smooth power transmission to rollers. Specialized bearing assemblies support continuous operation under high mechanical stress conditions.

The system's design prevents slippage through advanced friction control mechanisms. Modern controls allow operators to store and recall specific bending profiles.

Smart sensors monitor roller alignment and material position throughout the bending process. The integration of advanced systems ensures consistent quality across different material specifications.

Control Systems

Modern control systems enable precise management of every bending operation through digital interfaces.

Integration of bending machine components with advanced electronics ensures accurate material processing. Programmable logic controllers coordinate multiple functions while maintaining consistent bending quality and precision.

Key capabilities of control systems include:

Real-time monitoring of roller positions during bending cycles

Automated material thickness compensation for different plate specifications

Storage capacity for multiple custom bending programs

Touch-screen interfaces with intuitive graphical programming features

Remote diagnostics capabilities for maintenance scheduling

Integration with factory management systems for production tracking

Multi-language support for international operating environments

Emergency stop functions with redundant safety circuits

The control panel provides operators with comprehensive information about the machine's status. Digital displays show critical parameters like pressure, speed, and material position.

Advanced software algorithms calculate optimal bending sequences for complex shapes automatically. These systems incorporate material databases to adjust parameters for different metal types.

Interactive visualization tools help operators preview bending results before starting production. Machine learning capabilities improve bending accuracy through continuous process optimization.

Networked controls enable remote monitoring and adjustment of bending parameters remotely. The system architecture supports future upgrades through regular software updates.

Maintenance and Safety

Regular maintenance schedules ensure optimal performance and extend equipment service life.

Operators must implement rolling machine safety precautions during maintenance and operation procedures. Scheduled inspections identify potential issues before they affect production quality standards.

Essential maintenance practices include:

Daily lubrication of moving components and roller bearings

Weekly calibration checks of control systems

Monthly inspection of hydraulic systems for leaks

Regular testing of emergency stop mechanisms

Proper training programs help operators understand maintenance procedures and safety protocols. Documentation systems track all maintenance activities and safety compliance requirements.

Quality and Manufacturing Standards

Quality standards ensure consistent performance in metal forming across various industrial applications.

Leading plate-bending machine manufacturers follow strict guidelines to maintain production excellence. International certifications validate the manufacturing processes and final product quality standards.

Essential compliance requirements include:

ISO certification for quality management systems

CE marking for European safety standards

Safety protocols meeting OSHA requirements

Environmental sustainability guidelines for manufacturing processes

Regular inspections and testing procedures validate the performance of each machine component. Documentation systems track manufacturing processes from raw materials to final assembly.

Features of Himalaya Plate Bending Machine

Linear-guided roll movement ensures precise bending operations and enhanced structural stability.

The Himalaya plate bending machine features robust steel frames connected by a sturdy box-design chassis. Advanced hydraulic systems enable operation at variable capacities to optimize energy consumption.

Key features include:

Forged carbon steel rolls with specialized spline-based design for reliable performance

Linear guideways with machined roll movements for consistent parallel alignment

Tropicalized cooling system for continuous operation in high-temperature environments

Built-in cone bending capability for versatile manufacturing applications

Crown-machined rolls compensate for deflection during the bending process automatically. The planetary gear system reduces energy wastage while maintaining optimal speed control.

Integrated PLC controllers offer precise operation monitoring and preventive maintenance alerts. Surface-hardened rolls with chrome plating serve specialized industry requirements like pharmaceuticals.

Additional support features include powered conveyors and tilting tables for handling. A comprehensive control system ensures accurate parallel settings after cone bending operations.

Conclusion

Modern manufacturing demands high-precision equipment for consistent metal forming and shaping operations.

Leading plate-bending machine manufacturers continue to innovate with advanced control systems. The plate bending machine integrates sophisticated components to ensure reliable metal processing capabilities.

Essential industry requirements include:

Regular maintenance schedules to maintain optimal operational performance

Operator training programs for safe machine operation

Quality certification compliance for international manufacturing standards

Integration capabilities with modern factory management systems

Enhanced safety features and automated controls define the future of bending technology.

FAQS

Q: What is a plate bending machine used for?

A: Plate bending machines transform flat metal sheets into curved or cylindrical shapes for industrial applications. They serve critical roles in manufacturing tanks, vessels, and wind towers.

Q: What is the principle of a plate rolling machine?

A: The machine applies controlled mechanical force through synchronized rollers to bend metal plates. Three or four rollers work together to create precise curves and shapes.

Q: What is the working principle of rollers?

A: Rollers use mechanical pressure and synchronized movement to bend metal plates gradually. The top roller provides pressure while bottom rollers support and guide the material.

Q: What are the different types of bending machines?

A: Common types include three-roll, four-roll, variable geometry, and section bending machines. Each type serves specific bending requirements and material thicknesses.

Comments